Quality assurance

Rigorous quality control throughout the production process

Material Control

For material suppliers,Jiangsu Jinyuan may be an "picky" partner.Respect for true data,focus on processes and attention to traceable details,Jinyuan has created a strict evaluative and inspective system to ensure the stable quality from the square one.

Five Standards of Suppliers

Quality First

Excellent product quality and good brand reputation.

Specifications above all.

International product specifications,top standard and the specific requirements of customers.

Qualification required

Higher operation qualification and verification capital with complete corporate information.

Must-have requirements

Reasonable trade terms,faithful trade mode and precise trade contract

Top-tier service

Quality after-sales service.

Production Procedures

Precision details and high rigor have contributed to the quality of Jiangsu Jinyuan Forgings.Jinyuan has not only strictly controlled on all processes of its products but also seek the stability and reliability of the products. Traceability has run through the processes including cutting,heating,forging,cooling and machining.

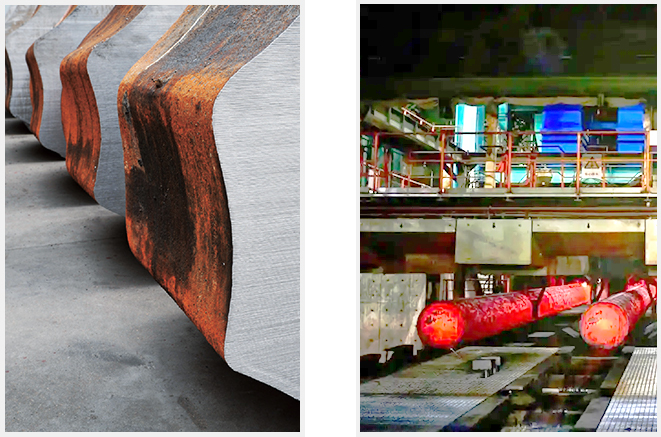

Ingot Cutting and Sectioning

According to customer orders and technical requirements,raw material is accurately prepared with tracing details.

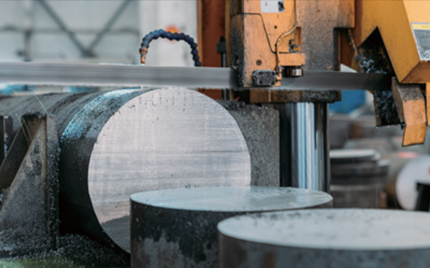

Heating

Heating furnaces are free of pollution and featured by low energy consumption,uniform heating and very small temperature difference between the core and surface of the workpiece.The temperature control system is applied to achieve precise control of temperature so as to improve overall quality with the support of company patents.

Forging

Workpieces of various types are forged according to the production process cards with required dimensions and forging ratio.

Heat Treatment

Overall mechanical properties of the workpiece,uniform structure and grain sizes can be improved by heat treatment after forging and quenching and tempering.

Machining

Proof machining & semi-finish machining can be completed with our 80nos horizontal and vertical lathes.

Final inspection identification and warehousing

Factory identification is marked and records and documents are filed.

Advanced Equipment

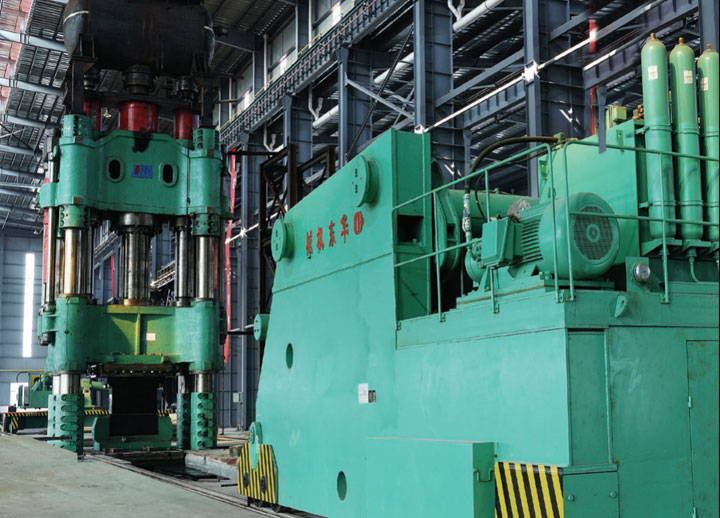

45MN hydraulic unit

Jiangsu Jinyuan possesses a leading 45MN free forging press in China with its supporting facilities of 70T forging crane,50T crane truck,6 natural gas heating furnaces and 6 post-forging heat treatment furnaces,which are all made by independent research and development control technologies and have advantages of automatic ignition,adjustment,and temperature control with high accuracy as well as the maximum tonnage of 30T in the production and is enjoying the advanced level in private enterprises.

Quality System

Total staff quality management,full-process quality assurance,comprehensive quality service—loyal to standards,exceeding standards,and customer satisfaction as the ultimate benchmark.

Continuously enhance competencies to persistently comply with international conventions,IMO,and classification society rules/standards.

+86-519-87190168

+86-519-87193518

+86-519-87190108

jinyuan@jinyuanforge.cn